Metal roofing is becoming a broad topic. You could talk about material, fastener and seam type, and pattern. As for material, there are 4 common metal roofing types to choose from. We’ll discuss the pros, cons, and the costs of each, along with the different designs and styles of metal roofs.

Metal Roofing Materials

The first choice to make when considering a metal roof is what material to pick.

Aluminum

Aluminum is a lightweight and durable choice for climates with a lot of rain. Because it never rusts, your aluminum roof can literally last a lifetime. It can also come in any design or color. You can buy aluminum roofing sheets stamped to look like shingles, wood shakes, or any other pattern. Most of the time, aluminum roofing comes pre-painted, and you may need to repaint it once in a while to maintain its look.

As for strength, though, an aluminum roof is very difficult to damage. In fact, if you get a stamped pattern, the structure of the material becomes even stronger even though it’s most likely recycled content. The majority of aluminum roofing (90%) comes from recycled pop cans, making it a very environmentally friendly choice.

On average, an aluminum roof will last 30 years or more without any major repairs or replacement needed. It costs an average of $3.15 per square foot if you have your builder or roofer install it for you. It’s not the least expensive metal roof, but it’s a lot more budget-friendly than something like copper or stainless steel.

The downside to aluminum is that it shows surface scratches easily. This doesn’t lessen the structural integrity of the roof, but it may need more maintenance to keep it looking nice. The thickness of aluminum roofing ranges from .019″ to .032″, depending on your pattern. Sheets stamped to look like shingles, shake, or tiles are thinner than the traditional standing seam metal roof style.

Galvalume Steel

This type of metal roofing is steel coated with a mixture of aluminum and zinc. Zinc galvanizes, or protects, steel. The word galvalume is a combination of the words galvanized and aluminum. The aluminum in the coating makes this roof very resistant to rust. It also makes it susceptible to showing scratches.

In general, you don’t want to get a galvalume steel roof with a lot of bends and folds in it. When you do, the aluminum coating on the roof stretches and becomes too thin in the folds, and so you might get rusting in those formed areas. It’s better to keep galvalume flat so that the coating doesn’t bend and crack.

You could coat a galvalume roof in clear acrylic to keep it sealed. Painting also helps, and most homeowners do paint their metal roofs.

The thickness is usually around .024″, and the material is commonly made of 35% recycled content. Galvalume costs about $3 per square foot.

Galvanized Steel

By itself, steel is very susceptible to rusting. That’s why it’s best to coat in something else. In the case of galvanized steel, manufacturers pour molten zinc over the steel and let it harden into a topcoat. The zinc “galvanizes” or “protects” the steel from corroding.

Galvanized steel comes in any pattern as the zinc is able to keep it coated despite bending to form the shapes. The life span of a galvanized steel roof really depends on how thick the zinc is. A rating of G-90 is common, meaning the roof is coated in 0.90 oz. zinc per square foot. That amount creates a fairly thick layer of zinc. You don’t want to buy lower than this unless you have a way to recoat the roof in zinc or other protective covering. Most galvanized roofs are also painted, both for looks and for added protection.

While zinc and paint do protect the steel from rusting, it doesn’t protect it as well as the aluminum-zinc mixture does in galvalume roofs, so if you live in an area with a lot of rain (and especially salt spray from the ocean), you probably shouldn’t choose galvanized steel.

The thickness is between .014 and .024″, depending on what gauge steel you choose. Recycled content comprises around 35% of galvanized steel roofs. Like galvalume, you can expect to pay about $3 per square foot for galvanized steel.

Copper

A copper roof looks very unique and attractive. It’s also quite expensive. In terms of price, steel is the least expensive, and aluminum falls in the middle. Because it is so high-cost, most people don’t use copper for their entire roof. They might use it to frame a dormer or other architectural features.

You can buy copper roofing in a variety of styles, but it’s most common in flat sheets. The copper can be colored naturally, but you don’t paint copper.

Though copper is not commonly used for an entire roof, you don’t want to use it in conjunction with other metal roofing materials. This is because the copper ages, forming a patina over time. This adds to the attractiveness and character of copper, but part of the process is that the copper color will runoff and could stain other metals.

It also stains brick and concrete, so whatever you use for your roofing material, make sure you redirect the water from the copper embellishments on your roof. You may have a dedicated gutter system for this area to direct the water into the ground or a flowerbed, where the color won’t stain.

Besides the aesthetic appeal of the patina, this layer also helps protect the copper. It typically takes 8-15 years to develop, but you can buy it pre-patinated to hurry the process along. If you have in a coastal region, the salt in the air will also make it develop faster.

Copper roofing can last over a hundred years, but if you don’t want to pay for full copper, you can also buy steel or aluminum roofs with a copper coating. This gives you the same look for a much lower cost. It won’t last as long as real copper, though. Full copper costs an average of $18 per square foot. That’s a lot more than the $3.15 for aluminum or $3 for galvanized galvalume steel.

The thickness of copper roofing is between .016 and .027″, depending on the pattern. Copper shingles are thinner than sheets with vertical seams. Like steel roofs, the recycled content is right around 35%.

Other Metal Roofing Materials

The four types of metal roofs we’ve covered above are the most common. You can buy them from any supplier in a variety of styles. If you’re building a new house or building, however, you can ask your architect to order a custom metal roof.

Possible options include zinc, titanium, stainless steel, and terne-coated steel. Terne-coated has a matte finish, as opposed to a shiny finish like stainless steel, because it is coated in a mixture of zinc and tin. These roofs will be more expensive because they’re custom-made by a metal fabricator rather than mass-produced.

Styles of Metal Roofing

What kind of look are you going for with your metal roof? Do you want it to look like a more traditional asphalt shingle or wood shake? Would you rather it look like scaled metal?

How about flat sheets with raised ridges? You can have any style with a metal roof; just remember that some roof material types, such as galvalume, doesn’t retain the integrity of their protective coating when shaped into anything other than flat sheets.

Shingle, Shake, and Tile

You might also hear this referred to collectively as stamped metal roofing. That’s because the shape is stamped into the metal to form the different looks.

Shingles resemble the most common roofing style in America, layered asphalt squares. Shake metal takes on the attractive look of uneven wood. Tiles look like clay tiles. All of them are very textured and stylish, adding a lot of interest to your home.

The benefit of employing these styles in metal is that the roof is longer lasting, more waterproof, and requires less maintenance. It’s also easier to install if not to repair. Because metal roofing comes in large sheets, you can apply a large section fairly quickly.

Many homeowners who want the durability of a metal roof choose one of these styles because they blend in with the styles of their neighbors’ homes.

Standing Seam

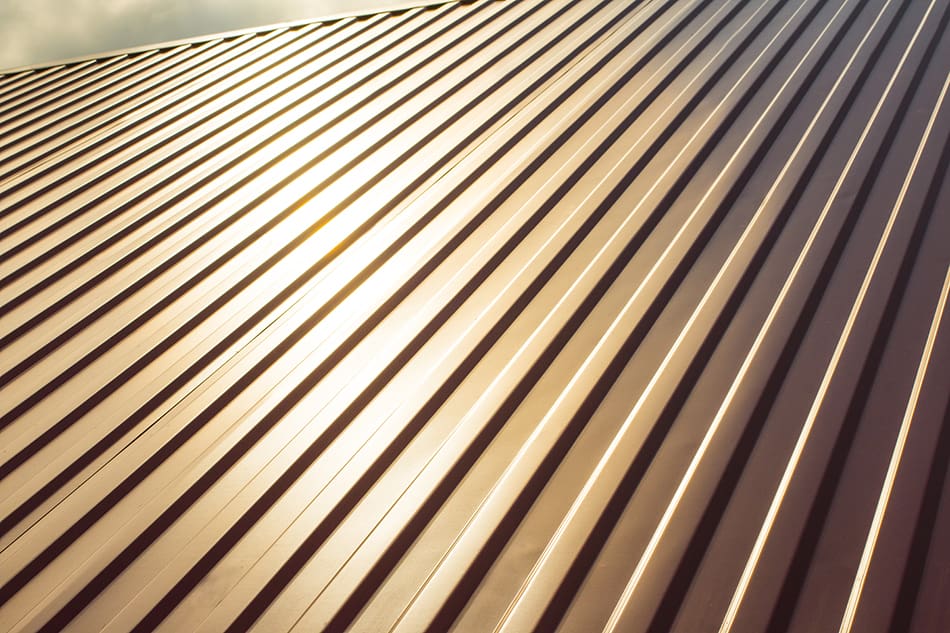

This is the traditional look of metal roofing. Roofing sheets in this style look best on commercial buildings and barns. But that’s only because of the wide panels.

If you want to use this style on your house, you certainly can; just choose a pattern with a panel width of 12 inches or less. This smaller spacing will fit better on a smaller structure like a house.

Sheet Roofing

These panels are relatively flat, though they can have a “crimp” or wave to them. They’re popular in rural and agricultural areas. If you leave them unpainted, they give the impression of being historical.

This is also the least expensive style of roofing, and it comes in larger panels than the more “formed” styles. Out of all the styles, it’s easiest to install, as you simply overlap the panels and drive in your fasteners (nails or screws) with a washer.

Types of Metal Roofing Installation

Besides the material and form of your metal roofing, you might also want to be careful in choosing how your metal roof is installed. This depends largely on how the panels are fastened down. The method of installation will somewhat affect the finished look of your roof as well as how easy it is to maintain.

Exposed Fasteners

A fastener is usually simply a screw or nail, though some brands of metal roofing require a specialty fastener.

An exposed fastener is one you see the top of when it’s driven in. The advantage of exposed fasteners is that they’re the easiest to install. You simply lay your panels of metal roofing, then drive the fastener in. Unlike asphalt shingles, metal roofing has the advantage of using washers on the fasteners to reduce any possibility of leaking through the fastener hole.

Using exposed fasteners gives the more traditional look of metal roofs, especially if used with sheet metal roofing. But if you’re going for a more refined, finished look, you may not want to see all your screw holes.

Hidden Fasteners

This design is popular in standing seam and stamped roofing. Instead of showing the nail or screw holes, you actually fasten the panels down, then cover the holes with the overlap of the next panel. The panels click and lock together to provide a watertight seal. They’re a little more complicated to install but look a lot more professional.

Metal Roofing Maintenance

So, metal roofing is supposed to last longer than asphalt shingles, wood shakes, clay tiles, etc., but what do you have to do to it to make it last as long as advertised?

First is simply washing your roof. Once a season, you can get up on your roof and wash the bird droppings, leaves, dust, salt, etc. off with soapy water and a brush. You can also use a pressure washer to spray the roof off and remove any tough materials. Just don’t use an abrasive brush. You don’t want to scratch the roof.

If you’re using galvalume or galvanized steel or any other type of metal roof with a coating, that coating is meant to protect the metal from rusting. Over time, however, that coating will wear off, so you’ll need to reapply a topcoat. If you have a roof with a thicker coating, it will last longer than those with a thinner coat, so it’s recommended to pay more off the bat for the thicker coating.

Of course, you won’t be reapplying a top coat of zinc or other metal mixture. You’ll most likely be applying a coat of polymer, such as Kynar. You can hire a professional to recoat your roof or do it yourself if you have the time. It’s not difficult.

It’s the same thing with a painted roof. Even faster than the coating, the paint will scratch, chip, or fade, and you’ll want to repaint the roof. Metal roofing isn’t like vinyl siding that you’ll never need to repaint.

To repaint your metal roof, use spray paint or a paint sprayer to ensure you get an even coat with no brush marks. You may need to apply a primer first to ensure the paint adheres to the metal. See your manufacturer’s info for the type of paint to use.