Unless you’re a martial arts expert who can karate chop boards in half, you’re going to need some sort of tool to cut wood. But what tool do you need? That depends on what type of cut you’re trying to make.

These are the various types of wood cutting tools and what to use them for.

Hand Tools for Cutting Wood

These non-powered tools make a variety of cuts in wood. Some are used to make very rough cuts, while others are used to make smooth finishing cuts.

The advantage of hand tools is that they’re less expensive than power tools. Of course, depending on your task, using a hand tool may take longer than using the corresponding power tool would.

Ax / Hatchet

Making the roughest of cuts is the trusty ax. Many artisan woodworkers prefer to fell their own trees so that they know exactly what type of lumber they’ll be working with. Once the tree is felled, you can exercise more control with the shorter version of the ax: the hatchet.

You can also use an ax to split logs for firewood, an excellent use for the leftover stump of the tree that you’re not going to use for anything else.

When you purchase an ax or hatchet, be sure to check the comfort of the handle. Because you’ll be swinging the ax and making an impact against the wood, you’ll need a handle that can absorb the blow. It should also be easy to grip without leaving blisters on your hands.

Rip Cut Saw

This is the epitome of the term “hand saw.” When someone pictures a hand saw, they’re most likely thinking of a rip cut saw. The teeth are very sharp, but they’re relatively far apart, meaning this tool will make fast, rough cuts.

You can buy rip cut saws in a variety of lengths, depending on the width of the wood you’re cutting and the length you’re comfortable handling. Longer blades are more difficult to control and more tiring to use, so use a shorter saw whenever possible.

Crosscut Saw

The other option people might think of as a general hand saw is the crosscut saw. It’s named crosscut because it’s designed to cut wood across the grain. Usually, this is cutting across the narrowest part of a piece of wood rather than the longer direction in which the grain runs.

A crosscut saw blade is thicker saws and has beveled teeth. It will make rough, fast cuts. To make your cutting job go even faster, you can buy two-person crosscut saws with a handle on both ends of the saw.

These two-person saws are also called felling saws because two people can stand on either side of a tree and push and pull the saw through the trunk.

Bow Saw

Another type of crosscut saw is the bow saw. Instead of having a wide blade, it has a narrow blade with a curved metal frame. The reason for this change is so that you can cut through a tree trunk or piece of lumber without having a thick blade being pinched by the wood. The bow stays outside of the cut.

The other advantage to a bow saw is that you can change the blade fairly cheaply. When you want to replace larger saw blades, as in a crosscut saw, it’s often easier to buy a whole new saw. Bow saw blades are inexpensive enough and easy enough to change that it makes sense to keep the frame and insert a new blade.

As with other saws, bow saws come in different sizes. They can be longer or shorter or have a wider or narrower bow frame. Think about the length and depth of the type of wood you want to cut with a bow saw and buy accordingly. You may want to have two bow saws, a smaller and a larger one.

Pruning Saw

A pruning saw is another rough-cut saw, but rather than having a straight blade like all the others, it has a curved blade. It also has a pistol grip rather than a handlebar grip.

It generally has a short blade, and the curvature is good for cutting round materials, such as a tree branch. Able to cut over a wider surface area (from the top and side, you could say), a pruning saw cuts through rounded materials faster than a straight saw.

Pole Saw

If you need to cut a branch that’s high overhead, you can buy or make a pole saw. A non-powered pole saw has a pruning blade on the end of it and telescopes to be longer or shorter. The pole itself usually extends to 16 feet, and the blade might be six or eight inches long. Because it’s on a pole, this type of saw is very difficult to control and tiring to use as you lift it overhead. Don’t expect to make precise cuts with this tool.

There are also powered versions of pole saws that have a non-telescoping pole and a mini-chainsaw on the end.

Back Saw

Now, we’re getting into saws that make a finer cut. The back saw gets its name from the reinforced frame along the top of the saw. You could call this area the back, and the surface where the teeth are the front.

A back saw is shorter than a lot of straight saws and has teeth that are closer together. The reinforced back makes it, so the blade doesn’t wobble as much as pull it and push it back and forth. You can also press down on the back of the saw to steady it even more. All this lends to creating a straight, smooth cut.

Coping Saw

Similar but much smaller than a bow saw is the coping saw. It has a thin blade held in place in a curved frame. The blade has small teeth spaced very closely together to make fine, delicate cuts. Again, the curved frame makes it so that your blade doesn’t get pinched between the two sides of the wood you’re cutting.

Like the bow saw, the blades on a coping saw are meant to be changed. And you will want to change them frequently. Besides the fact that the small teeth will wear down more quickly, these skinny blades are also fairly fragile. It’s easy to bend or break one if you don’t keep the saw straight as you cut.

Fret Saw

A fret saw looks just like a coping saw, except the blade is shorter, and the frame extends even further. This allows you to make short cuts through a thicker material. Because the blade isn’t as long, it’s not as susceptible to breaking, but because there are fewer teeth, they will wear down faster than those on a longer blade.

Japanese Saw

This is a unique type of saw in that you don’t push and pull it to make a cut; you pull it only. If you’re careful to control the blade, you can use this more intentional motion to make precise, fine cuts, though you’ll likely need to practice with this type of saw to get the hang of it.

Japanese saws come in a variety of sizes, so get one that corresponds best to the length of cut you need to make and that you can control easily.

Keyhole Saw

A keyhole saw is kind of like a pumpkin carving knife. It has a sharp point and serrated teeth. For woodworking, you’d use it like a jigsaw, cutting a hole in the wood, then inserting the blade and using it to cut curves or cutouts in the wood.

Wallboard Saw

A wallboard saw is much like a keyhole saw, but it has teeth wider apart for making rougher cuts. It might also have teeth on both the front and back to allow you to cut in both directions.

Veneer Saw

This is another double-edged saw, but it’s designed to make fine cuts in thin materials. The blade is very short to give you maximum control over the tool.

Plane

You can use a plane to scrape material off of wood. It has a razor-like blade on the bottom that you can shorten or extend to scrape off more or less material. To use the plane, you press down on the top and push it across the surface of the wood. The blade will catch and peel off the surface material.

There are different types of planes, including bench, smoothing, compass, and shoulder planes. A bench plane and a smoothing plane are for working on flat surfaces, while a compass plane is used for curved surfaces. A shoulder plane allows you to make joints in wood.

Chisels

Like planes, you can use a chisel to scrape material off of wood. You can also make cutouts in the surface of the wood. To do so, you’ll need a hammer or mallet to strike the back of the chisel and drive the blade into the wood. They are usually straight-edged, but you can also buy them with a beveled edge for making more decorative cuts.

Using a chisel tool accurately takes a lot of practice, and the force you use to drive the chisel in will depend on the type of wood you’re working with. It’s best to make a couple of test strikes into spare wood before starting on your workpiece.

Power Tools For Cutting Wood

These wood-cutting tools can help you perform a variety of tasks very quickly. Some do exactly what the hand tools could (but faster), while others allow you to cut wood in ways a hand tool never could.

Read through these descriptions to see which wood-cutting power tools would be worth the investment to you.

Chain Saw

A chain makes the roughest cut of all the power tools available. A thick chain with teeth rips through the wood. In most cases, you can cut through a tree trunk or branch very quickly with a chainsaw, but it takes a lot of practice to make artisanal cuts with this tool

You can buy them in different lengths to give you more control or help you cut through thicker materials. You can also buy them in gas, battery, or electricity-powered models.

You will need to adjust or change the chain quite frequently, as the chain can loosen up after repeated usage. You can also sharpen the chain if you’re not ready to replace it.

Reciprocating Saw

This type of saw looks a little like a machine gun. It has a rifle grip and a barrel that houses all the machinery. At the end of the muzzle is a short blade that moves in and out.

It’s a versatile type of tool because it cuts through a wide variety of materials, and you can use it at any angle you can hold it. The blades are cheap and easy to replace. Just don’t expect to make very cuts with this kind of saw.

Sawzall was the original maker of this type of saw, and some people still refer to all reciprocating saws as Sawzalls.

Oscillating Saw

If you like the idea of a reciprocating saw, you’ll love the oscillating saw. Instead of moving in and out, the end of the oscillating saw moves back and forth. If you hold the tool steady, you can make very precise cuts with it. You can also attach different heads to the oscillating tool to make different cuts and shapes in the woods.

Besides cutting wood, you could use an oscillating tool to grind, scrape, sand, or remove compound material.

Attachments for an oscillating tool aren’t very large, so you won’t be able to make deep cuts with this type of saw, but they’re great for small cuts and detail work.

Jigsaw

The jigsaw is a lot like a reciprocating saw in that the blade moves up and down to make a cut. Unlike a reciprocating saw, you can use a jigsaw to make very precise cuts. This is what you would use to cut out designs or patterns in your wood.

The saw has a guide that allows you to place the tool flat on the surface of a board. The blade hangs down and cuts forward. As you’re cutting, you can turn the saw to make the blade cut in a different direction. You can also change out the blade very cheaply when one gets worn.

Unfortunately, jigsaw blades are not very long, so you won’t be able to cut through thick materials with a jigsaw.

Scroll Saw

A scroll saw is a stationary jigsaw. It has a table on which you lay your wood, then position the wood however you need to against the blade. The blade moves up and down. It can create very smooth cuts, and you can adjust the speed of the blade to give you greater control over the project.

Spiral Saw

This is like a cross between a reciprocating saw, a drill, and a jigsaw. You can change out the bits for whatever type of material you’re cutting. You handle the tool like a reciprocating saw, but instead of moving back and forth or up and down, the blade spins. The result is that it’s very easy to handle, and you can change directions as you cut, just like a jigsaw.

Hole Saw

These are drill bits that can make a round hole in the wood. They have a circular end with saw teeth all around the rim to cut a fine hole. You can buy these bits in smaller and larger sizes to make any diameter of the hole you need.

Circular Saw

A circular saw has a circular disc blade that spins. You use it by running the saw over the wood you’re cutting. You can set the depth of the blade to cut through thicker or thinner materials, and you can also buy saws that take smaller or larger blades. The accuracy of the cut depends on how steady your hand is as you glide the saw across the board.

You can buy finer or coarser blades, depending on your purpose. Coarse blades cut faster, but finer blades make smoother cuts. The difference is whether the teeth are longer or shorter and how far the space between them is.

Circular saws don’t require much maintenance, except for changing the blade when it becomes too worn. When a blade dulls, it will rip the wood instead of cutting through it smoothly.

You may also hear circular saws referred to as buzz saws.

Miter Saw

Like a circular saw, a miter saw has a changeable circular blade. The difference is that a miter saw is stationary. You lay the board across the base and lower the blade onto the wood. It also won’t make long cuts. The primary purpose is to cut the ends of trim work to angle it.

Compound Miter Saw

A compound miter saw can be used to make simple angle cuts, but you can also tilt the blade to make cut two angles at once. It might take some time to get your head around, but once you understand what a compound miter saw is for, you’ll be able to hang crown molding and create other complex trim work much more quickly.

Stationary Band Saw

With most tools, you would bring the tool to the wood. In this case, you’re bringing the wood to the tool. It has a thin blade standing upright that can make fine cuts in wood. Depending on how you feed the wood toward the blade, you can make straight or angled cuts. You can even turn the wood while the blade is cutting to make patterns in the wood.

If you stand a board up, you could feed it through the band to shave the entire piece thinner. In this case, you’d want a fence guide to keep the board straight so that you get an even cut.

Because a band saw has a thin blade, you should expect to change it often.

Portable Band Saw

You can also buy a portable band saw, but due to its smaller size, this version won’t be as versatile as a stationary band saw is. For one, the blade isn’t as long, so you may not be able to use it on thicker materials. Two, you can’t make as precise of cuts because you have to hold the saw while clamping down the wood.

Still, if you want to cut thin pieces of wood (typically 3-4 inches thick) quickly and accurately, a portable band saw will do the trick.

Table Saw

A table saw is like a stationary circular saw. You set the depth of the blade, then feed the wood through the blade. Setting guides up on the side of the table will help you keep the board straight as you feed it through.

Panel Saw

These are the larger versions of table saws and may even stand upright, in which case, you would lift the board onto the guide and adjust the height of the cutting position. These are used to cut large pieces of plywood that you don’t want to balance on a table saw.

Flooring Saw

A flooring saw is another tool that combines the concepts of multiple saws. This one is like a circular saw, table saw, and miter saw all in one. It’s used to cut floorboards to size and angle, but you can obviously use it for more than just flooring.

You adjust the angle of the cut and then glide the blade over the wood with the help of a fixed guide to ensure you get a straight cut.

Track Saw

Like a flooring saw, this is a circular saw on rails. It glides over your piece of wood, ensuring you get a straight cut as long as you’ve lined it up properly. Like circular saws, you can adjust the depth.

Router

Getting away from saws, a router is used to cut grooves and patterns in the wood. You can adjust the depth to cut through the wood or make designs in the surface.

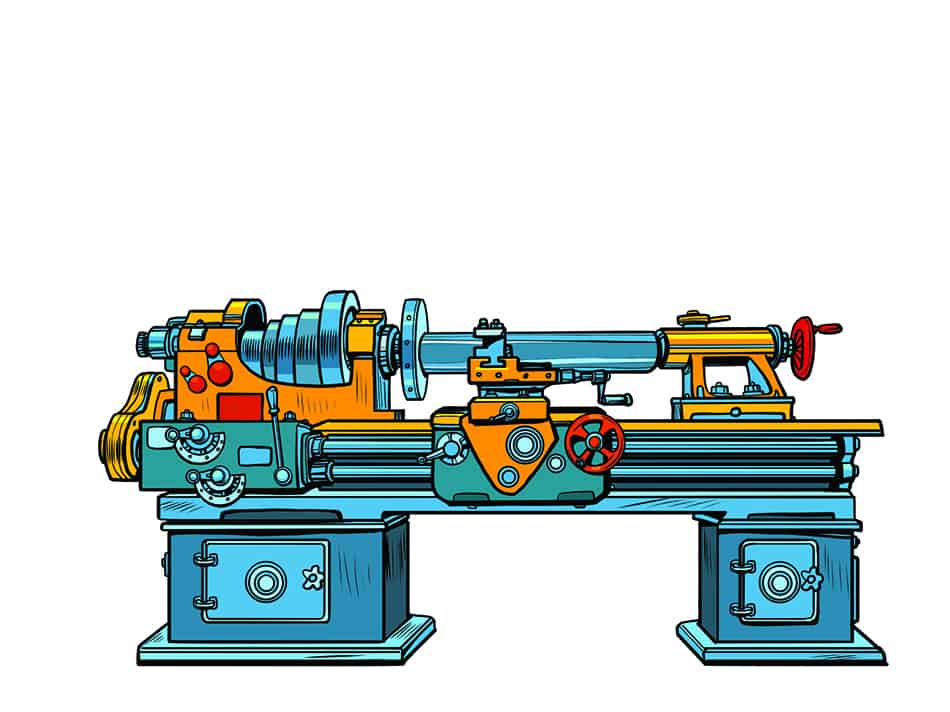

Lathe

A lathe is another stationary tool, but rather than cutting through the wood, you would use it to cut rounded grooves and patterns into it. The lathe bit spins, and you hold the wood up to it, turning it so that lathe chisels the wood evenly all the way around. By inserting differently sized chisel bits, you can create differently sized grooves in the wood.