If you’ve been wanting to take your lathing skills to the next level, then you’d have to familiarize yourself with lathe tools. There are plenty of lathe tools that you can choose from. Suffice it to say, there’s a lathe tool that you can use regardless of the DIY project that you have in mind.

What Is a Lathe Tool?

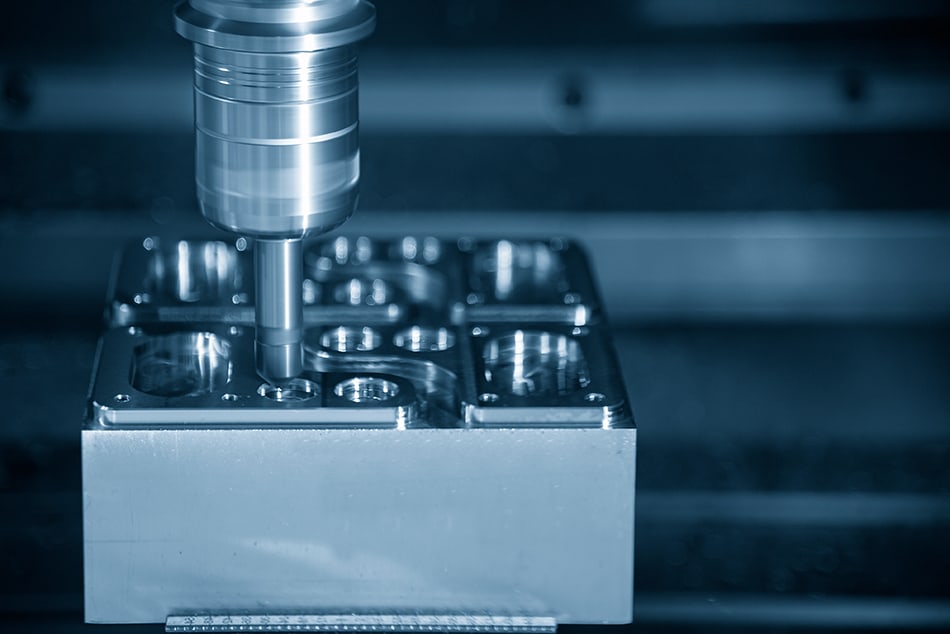

As you may deduce from its name, a lathe tool is an instrument or piece of equipment used on a lathe machine, which is considered the grandfather of machine tools. The lathe machine is used for shaping materials ranging from metal, wood, and glass. It can be used in applications such as metalworking, woodworking, and glass working, among others. It works through a simple hold and rotate mechanism.

Depending on its purpose, a lathe tool can cut, drill, sand, knurl, turn, or deform materials. Simply put, lathe tools make the lathe machine highly versatile. It’s one good reason why despite its age—it is believed to date back to 1300 BC—the lathe machine remains highly popular among wood and metalworkers up to this day.

Learn more about the various types of lathe tools so you can decide what’s going to work best for your wood or metalworking project.

Types of Lathe tools

Boring Bars

Boring bars are commonly found in machine shops because of their versatility and practicality. You can use it for drilling or creating a hole in a workpiece. It’s also ideal for reaming and boring or enlarging an existing hole. This is a tool you’d want to have when building a table. Or making room for larger screws in a project you’re building.

There are three types of boring bars. The first, high-speed steel, is cheap and tough. But it’s not as fast in cutting as the second type, the brazed carbide. This boring bar is also more capable of tolerating heat. The third type is the indexable carbide, which is known for being cost-effective.

Knurling Tool

When you need to create concave bumps on a workpiece, you’ll have to do the non-cutting technique called knurling.

Knurling has various purposes, such as increasing the grip of the fingers to grasp knurled parts. It can also be used for repairing wear on a machined part. It can also be utilized during the assembly of low-precision components.

Cylindrical parts like round nuts and screw heads have rough bumps. The same can be said for tool handles, barbell bars, grips of pistols, and control knobs.

When knurling, you’ll need a knurling tool. This is a lathe tool that comes with a handle and a knurling wheel. On a lathe machine, it works with the turning lathe set and the chuck mounted. When the chuck rotates at a low speed, the knurling tool presses against a piece of round section of the workpiece.

The pressure is then increased slowly until the desired pattern is formed. Knurled portions can vary depending on the patterns produced. Some are straight-knurled; others are cross-knurled, while some can be spiraled. There are also various types of knurling tools. For example, the self-centering type has two knurl wheels designed to cut straight and diamond patterns.

Chamfering Tool

You’ll need a chamfering tool if you need to break off an extreme edge on a workpiece. It’s useful in smoothing sharp edges on a workpiece.

There are two types of chamfering tools for lathe machines—vertically oriented and the second is horizontally oriented. You can find differently-sized and shaped chamfering tools, giving you flexibility depending on your production needs.

Facing Tool

If you need to flatten and smoothen the surface of a workpiece by removing a metal part from its end, then you’ll need a facing or turning tool. This lathe tool can also come in handy when making a diameter smaller. It is, therefore, not surprising that this tool is essential for various projects.

With a facing tool, you can slice a flat surface that is perpendicular to the rotational axis of the workpiece. To use a facing tool, you will need to mount it into a tool holder resting on the carriage of the lathe. It will then be fed perpendicularly across the rotational axis of the part while it spins.

You can hand-feed the machine or opt for the power feed portion. If you desire a smoother surface, it is recommended that you use the latter because of its constant feed rate.

Parting Tool

Another essential type of tool that you should invest in for your lathe is the parting tool. This typically makes use of a blade plunged directly into the workpiece to cut it off at a determined length.

You can use the parting tool to remove the finished end of a workpiece or slicing the head of a bolt. In short, a parting tool comes in handy when you need to cut off certain sections of your workpiece or resize pieces so that it would fit together properly. Aside from its versatility, you’d love that the parting tool is easy to maintain. Its short edge makes it easy to sharpen.

You’ll also need to apply a little pressure to the tool against the wheel when sharpening it. Oftentimes, the weight of the parting tool is enough for it to be sharpened well.

Parting tools come in many forms and sizes. However, for beginners, the 6mm parallel parting tool is highly recommended. It is easy to use in parting timber into two pieces. You can also use it in making sizing cuts and turning beads.

There are other kinds of parting tools that you can come across with. The diamond parting tool is named as such because of the way its blade is shaped. Since its sides are removed, the tool can operate with less binding in the cut and generate less heat in the process. Tapered or flared parting tools also minimize the binding of the tool while in use.

Finally, a fluted parting tool is fluted along the length. It’s something you’d want to use if you want a clean cut on the base of your projects, requiring minimal cleanup after removing it from the lathe machine.

Channeling Tool

You may find the channeling tool unnecessary for most of your projects. But from time to time, this will be useful to you. With a channeling tool, you can create circular and shallow grooves like O-ring grooves. It’s essential to the grooving technique or creation of narrow holes on a workpiece.

You might mistake channeling tools to narrow flat chisels. However, the most distinguishing feature of a channeling tool is the narrowness of its shaft above the cutting edge when you view it from above. This feature allows the tool to be inserted into deep hollows and crevices.

It’s easier to procure a channeling tool when you buy it in a set, along with other lathe tools. Look for one made of high-quality materials such as steel or carbide. Cutting channels into your stock will be easy when you use a channeling tool with a carbide tip.

Grinding Wheel

A grinding wheel is a lathe tool featuring thousands of cutting points on the surface. These are abrasive grains held together by a bond matrix and separated by pores. The latter are hollow spaces in between the abrasive grains and bonds.

With a grinding wheel, you can cut hardened steel. You can also produce smooth finishes with the use of a grinding wheel. This lathe tool can also be relied upon in cutting high-grade alloy steels.

It is often added to a lathe machine for the sake of convenience. Doing so allows the user to harness several functions into one tool. The grinding wheel is not only simple to use but also a practical addition for anyone who operates a lathe.

In choosing a grinding wheel, you must take into consideration several factors. One is the grinding wheel grade, which is indicative of the holding power of the bond. Soft grades are best for hard materials like steels and carbides. It is also best for large areas of contact and quick stock removal. On the other hand, hard grades are recommended for cutting soft materials and when working on small or narrow areas on contact. Grinding wheels with hard grades also tend to have a longer wheel life.

You should also consider the material that you plan to grind and how hard or soft it is. Moreover, look into the stock that you need to remove from the material.

Woodworking Chisels

If you’re into woodworking, one of the most crucial lathe tools you should invest in is a woodworking chisel. Suffice it to say, it can help you complete a lot of projects. Similar to a channeling tool, a woodworking chisel is usually packaged or sold in a set. Woodworking chisel sets provide a lot of versatility and choices for their users regardless of their skill or experience levels.

In shopping for a woodworking chisel, there are several things that you should consider. One is the handle of the chisel. Many people who are into woodworking say this is the most important consideration in choosing a chisel set. The handle must be comfortable to use. It should be powerfully gripped to prevent slipping when working. You’d also want it to be durable so that you can get your money’s worth.

It can also keep you from frequenting the shops and looking for a replacement. Finally, you naturally want a reasonably priced woodworking chisel. More often than not, the cost of a woodworking chisel is determined by its design and construction.

Skew Chisel

You’d likely get a skew chisel in a woodworking chisel set. But it’s still reasonable to cite the skew chisel in particular. After all, you’ll need it if you want to give a smooth finish to your woodworking project. The skew chisel would also come in handy in projects where a piece of wood requires final touches before completion. You can also use a skew chisel in turning beads and making V and pummel cuts.

For many woodworkers, the skew chisel is the most daunting of woodturning tools. If you’re a novice woodworker, you may likely find it intimidating. After all, a slight misstep in using it can result in a dig-in or gouge of the wood. However, being careful and applying the proper techniques can easily avoid these unwanted scenarios.

The skew chisel is characterized by its long and flat chisel. The chisel is also bevel-edged. It has an angled tip. The long point of its cutting edge is referred to as the toe, while the shortest point is called the heel.

Like most lathe tools, skew chisels come in various sizes and forms. Skew chisels may vary in cross-sections. Some are round, while others are oval and rectangular. Widths may range from ¼ inch to 1 ½ inch. However, skew chisels operate the same way.

Spindle Gouges

Here’s another key tool you’ll need to have when working with a lathe machine—spindle gouge. It’s a handy tool for putting coves or forming grooves in wood pieces. This purpose makes the spindle gouge different from a normal chisel.

Spindle gouge features a round metal shaft with a wide-open and shallow U-shaped flute. The latter divides the metal shaft in half. The spindle gouge is therefore descriptively referred to as the shallow fluted gouge. And because lesser materials are surrounding its tip, the spindle gouge is less fortified compared to another tool that it is often compared with, the bowl gouge.

Aside from its shallow flute, the spindle gouge is known for its elliptical cutting edge. This allows expert woodworkers to use it for cutting with the sides of the tool. It’s particularly useful in rolling beads and shaping coves.

The tip of a spindle gouge is relatively flat. It can be sharpened to a finer, thinner tip, which makes it useful in detailing. You can make precise detail cuts on bowl exteriors and spindles with it. You can also shape beads and cut coves on spindles with a spindle gouge. It can also be suitable for faceplate work.

It should be noted that a spindle gouge lacks side wings capable of cutting. While you can turn it to a 90-degree angle for scraping, most woodworkers do not consider this a cutting technique. The spindle gouge is also a poor choice for shaping cylinders, making straight-line cuts like tapers, and roughing.

Spindle gouges come in various sizes. If you are using or buying one for the first time, consider the 3/8-inch variety as it is the most versatile. You can also add other sizes and variations depending on the requirements of your project.

Bowl Gouges

As mentioned earlier, bowl gouges are often compared with spindle gouges. But it’s important to note that these two tools have many differences. For one, a bowl gouge is better at making deeper gouges in wood pieces.

Most bowl gouges today have three parts: handle, flute, and rod. Bowl gouges usually have a long handle, around 16 inches in length, for enhanced leverage. The flute, on the other hand, is deeply cut to improve chip-cutting action. And the rod is typically solid round to make the bowl gouge extra strong.

If you’re shopping for a bowl gouge, you might get confused with the sizing of this tool. Manufacturers use two varied systems to size this lathe tool, which can be perplexing to most woodworkers, especially novice ones. The English system is the most commonly used. In this system, the size of the gouge is around the width of the flute.

The other system, the North American sizing, has the size of the gouge the same as that of the diameter of the rod. As such, a bowl gouge in the English system is usually smaller than in the other sizing system.

While bowl gouges are available in various sizes, you don’t need to procure a whole set. The general rule of thumb is to buy a ½ inch gouge (English system) if you have a standard-sized lathe machine.

Aside from the sizing of bowl gouges, you’ll have to be particular about the build quality. It’s advisable to buy well-built bowl gouges that can last for a long while. Most experts suggest getting a bowl gouge made from high-speed steel as it can resist wearing better and longer compared with those manufactured from high carbon steel. It won’t also be softened by overheating.

Detail Gouges

The detail gouge is similar to the spindle gouge but comes with a heavier cross-section. Its flute is also shallower compared to that of the spindle gouge. This leaves more metal under the flute for lesser vibration and smoother cuts. With its fingernail point and long bevel, the detail gouge can cut decorative grooves and fine detail on beads, bowls, and spindles.

It is common for the detail gouge and spindle gouge to be used interchangeably. But you’ll find the detail gouge a better choice for heavy cutting because of the presence of more metal under the flute. On the other hand, the spindle gouge is better at 30-degrees bevel.

Scraper Tools

You’ll find scraper tools essential when you are nearing the completion of a woodworking project. With a scraper tool, you can finish the convex and flat bottom sections of a woodworking project. The good news is that most hardware outlets sell scraping tools. Moreover, this type of lathe tool is also relatively easy to use.

Scrapers are made from flat stock in different widths and thicknesses. These tools are sharpened to yield a burr for cutting wood at a blunt angle. These lathe tools aren’t capable of producing a finish as smooth as a gouge. But make no mistake about it, this tool can be handy in other scenarios wherein a gouge would be difficult to use.

You can rely on a scraper tool in making tiny repetitive coves in awkward or hard to reach areas of a wood piece. And unlike a gouge, it can make an undercut like captive rings on bowls and spindle work. It can also make hollow forms with the interiors turned via a tiny opening.

Scraper tools are made from high-speed steel for optimum performance. These tools can also be reshaped into various profiles depending on the needs of the user.

Scraper tools also come in different types or varieties. One popular type is the large dome scraper best used for faceplate work, particularly bowls. It can work both inside and outside. There’s also the straight edge scraper that can make things flat.

Wood Beading and Parting Tool

The beading and parting tool is not only stable but provides many uses. It can be used for general parting operations as well as creating patterns, cutting beads, and spigots.

On the surface, a wood beading and parting tool may be no different from an ordinary parting tool. But you should realize that this tool is different in some important ways. For one, a wood beading and parting tool can make more shallow cuts compared to a parting tool. It can also be better suited for forming beads. You’d find a wood and parting tool handy when adding convex details to your woodwork.

Because of the essential work that a wood beading/parting tool does, it is not surprising that most woodworkers have this type of lathe tool. You will likely find one at most retailers.

In shopping for a beading and parting tool, look for one with blades made of high-speed steel. You’d also want a beading and parting tool that has stable handles. The handle must also be designed in such a way that you can comfortably grip it.