Ceiling fans are a very useful appliance that can make a room feel more comfortable. They do not alter the temperature of a room but instead redistribute air in a more advantageous way.

Ceiling fans are commonly used during summer when they push cool air downwards to create a refreshing breeze, but they can also be utilized in winter to drag cool air upwards to make a room feel warmer. They use very little energy and can therefore also save money spent on heating costs or air conditioners.

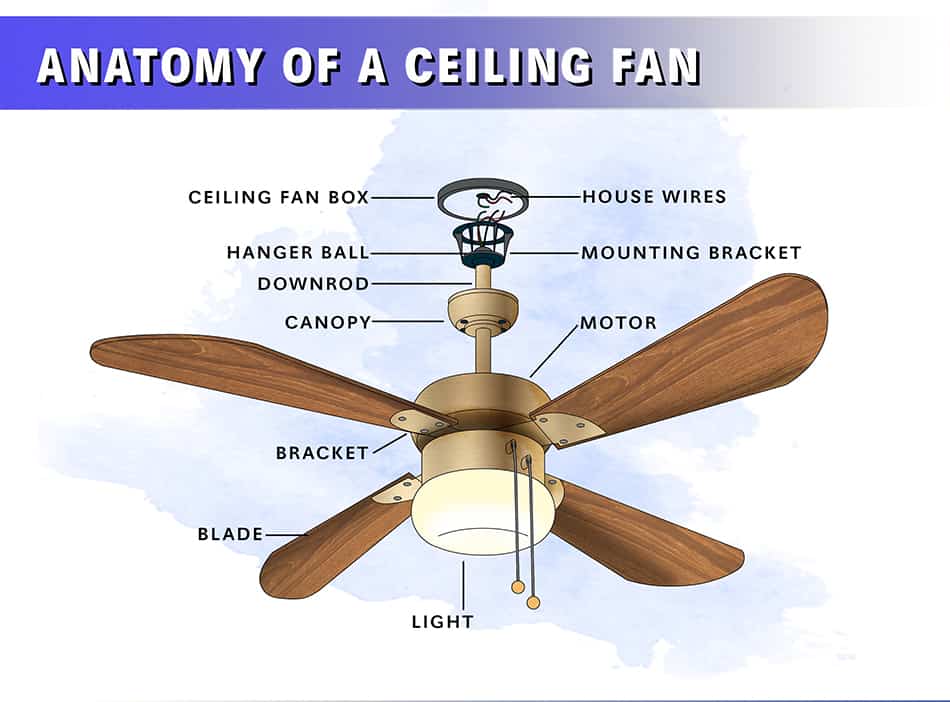

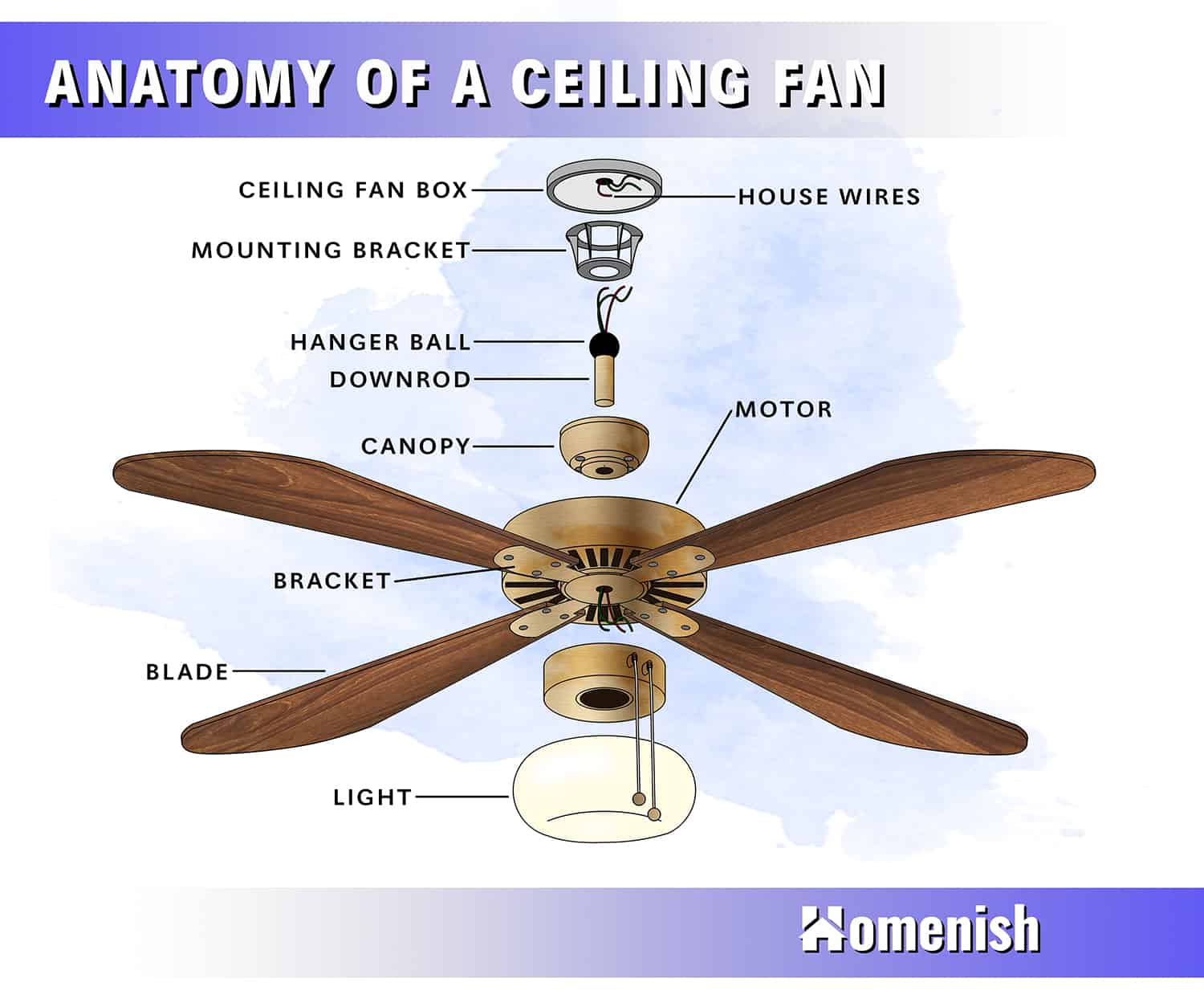

The components of a ceiling fan are:

Parts of a Ceiling Fan

Here is a diagram that identifies the major parts of a ceiling fan.

Motor

The electric motor of a ceiling fan is the beating heart of the appliance. It is responsible for turning the fan blades by converting electrical energy into mechanical energy.

This is achieved through the use of coils that turn in a clockwise direction after a magnetic field is generated when the electrical current hits them. The turning motion of the coils is transferred to the fan blades, causing them to turn.

Motor Housing

This is the covering around the motor, which hides it from view. This will usually be made from metal and can be plain and simple or decorative. The only function of the motor housing is to give the ceiling fan a neat and streamlined look by preventing the inner workings of the appliance from being seen.

Mounting Mechanism

The mounting mechanism is the type of fixture used to attach the fan to the ceiling. In traditional ceiling fans, the most common types of mounting mechanisms are ball and socket systems and J-hook and shackle clamps. A ball and socket system is best for use on vaulted ceilings, as it allows the fan to move freely.

This type of mechanism works with a ceiling-mounted bracket in which a fitting on the end of the downrod can securely rest inside. J-hook and shackle clamp systems are more common in older ceiling fans or heavy-duty ceiling fans intended for industrial and commercial use. In this mechanism, the fan is mounted onto a hook that is fitted within the ceiling, with a rubber grommet added to reduce vibration.

Low ceilings will benefit from a flush mount system where the motor housing appears to be fitted against the ceiling, with no downrod in between like a traditional ceiling fan. The benefit of this is that it increases head height in the room by fitting the fan closer to the ceiling, but as the blades circulate nearer to the ceiling, the distribution of air is reduced.

Downrod

The downrod is simply a piece of metal pipe that joins the motor housing to the mounting mechanism. It can vary in length depending on the style and design of the fan.

Longer downrods will suspend the ceiling fan at a lower level, while shorter downrods will hold the fan closer to the ceiling. Some ceiling fans, usually those intended for low ceilings, have no downrod at all.

Fan Blades

The fan blades are the long wings that extend outwards from the center of the fan. These are also sometimes known as paddles, and they can be made from different materials, including plastic, steel, plywood, solid wood, and aluminum.

Fan blades are positioned at an angle of 12 degrees to either drag air upwards or push air downwards, depending on whether you have the fan set at a clockwise or counterclockwise spin. The turning of the fan blades is what causes the air to be circulated around the room, either helping you to feel cooler or warmer.

In winter, the ceiling fan blades should be set to a clockwise spin which will drag the cool air up towards the ceiling and help to redistribute warm air. This makes the room feel more comfortable and can save on heating bills.

In summer, the fan blades should turn counterclockwise, which will push cool air downwards and create the effect of a cool breeze without actually altering the temperature of the room.

Ceiling fans most commonly have four or five fan blades, especially for fans designed for residential use. Generally, the more blades a fan has, the quieter it will be. However, fans with three blades are becoming a popular choice as they have a more minimalist style that fits better with modern decor.

Fan Blade Brackets

The fan blade brackets are also known as fan blade irons or hinges, and they are the part of a ceiling fan that attaches the fan blades to the central part of the fan.

Flywheel

The flywheel is usually made from rubber or plastic, though it can also be made from metal. It is the component onto which the fan blade brackets are attached, connecting them to the motor. Flywheels are prone to deterioration over time or with heavy use and are frequently the cause of ceiling fans breaking down.

Lamps

Not all ceiling fans have lighting attached, but many do especially traditional residential ceiling fans. In the case where the installation of a ceiling fan has replaced a ceiling light, choose a fan with downlights.

These lamps direct light downwards to create a well-lit space which is ideal for regularly used rooms such as kitchens and living rooms. For more ambient light, for example, in a bedroom or dining room, ceiling fans can be fitted with uplights. These direct light at the ceiling for a more subtle glow.

Pull Cord

A pull cord or pull chain can be made of metal beading or a thick fabric string. These cords dangle down from the fan to a height that users are able to easily reach but which do not get in the way.

Depending on the design of the ceiling fan, the pull cords can be used to turn the fan on and off, increase or decrease speed, change the direction of the fan blades, and turn the lamps on or off. Some fans might have several chains which coordinate with different operations, while some fans may just have one pull chain.