Cement boards come in various sizes as standard, with each size intended for different uses. Here we look at the sizes of cement board available and which applications are best used for in-home renovation.

What is Cement Board?

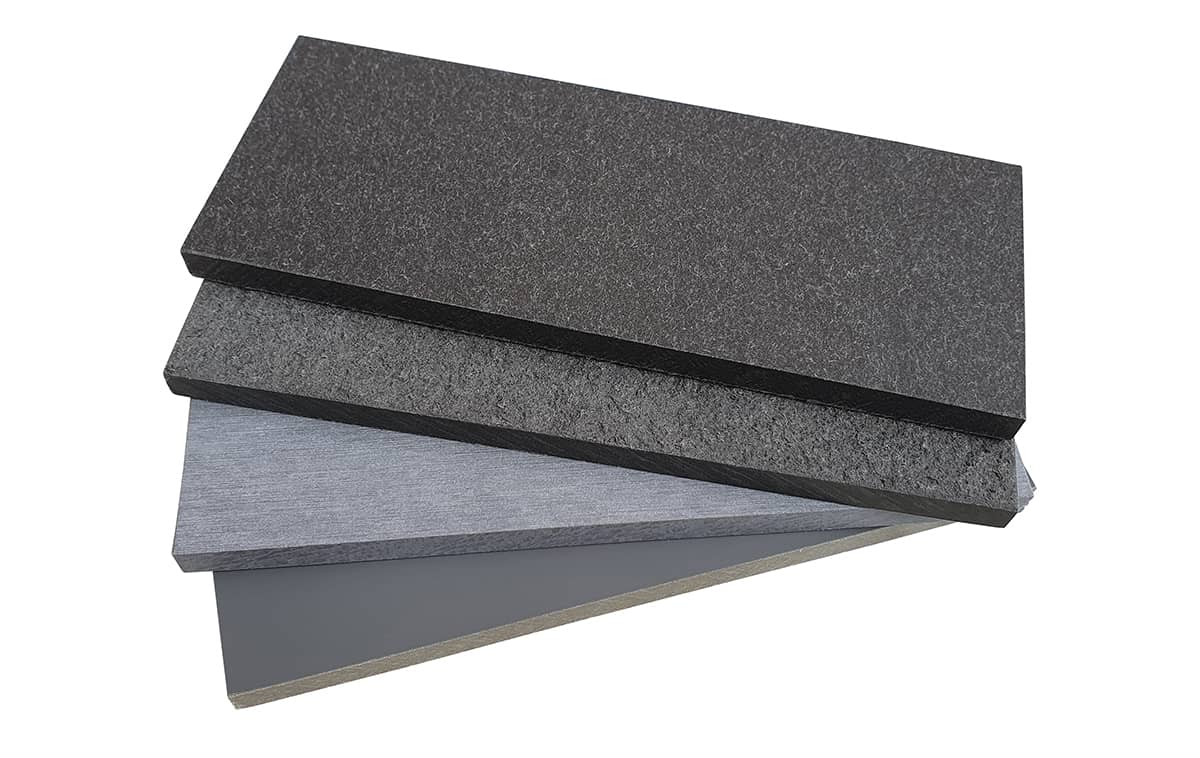

Cement boards are a type of prefabricated board which is made from a mixture of water, cement, silica, limestone flour, and fiberglass particles.

They are used as a backing board for tiled surfaces to create a more professional finish and to increase the durability and longevity of the wall.

How are Cement Boards Used?

Cement boards are resistant to moisture, rot, mold, decomposition, shrinkage or expansion, due to the fact that they do not contain any organic matter.

This makes them an ideal moisture-resistant backing for tiles, especially behind bathtubs and shower stalls where moisture levels are high.

Cement boards are also easy to work with; they are porous, and therefore grout, mortar, and tile adhesive adhere to them really well, holding tiles in place more securely.

They are also easy to cut with a various hand or power tools and can be screwed or drilled through with ease.

Cement Board Sizes

Cement boards come in a standard size of 5 feet by 3 feet. They are made in these dimensions to make them easy to manage while covering a large space without joins, as this can increase vulnerability. Standard depth sizes of cement boards are ¼ inch, ½ inch, and ⅝ inch.

The depth of the boards is going to make a big difference to the weight; a ¼ inch board measuring 5 feet by 3 feet will weigh around 30 pounds, while a ½ inch board of the same dimensions will weigh as much as 44 pounds.

The various sizes of cement boards have designated uses, with some being better suited to specific areas than others.

Quarter Inch Cement Board

Cement boards with a thickness of ¼ inch are designed to be used under tiles on flooring and countertops. Manufacturers of cement boards recommend that in order to use cement boards under floor tiles, you should install a ⅝ inch plywood subfloor or OSB underlay first. If your floor surface is made from cement, then additional cement boards won’t be necessary.

Although ¼ inch cement boards can be used as a backing for floor tiles, it doesn’t necessarily make it the best option. ½ inch cement boards can also be used for floor backing and have the added benefit of creating a more soundproof environment when used between different levels in a home.

However, a ¼ inch board is much more manageable to install, especially if you are working alone, and it is also less strenuous to cut down to size or to screw in place.

Half-Inch Cement Board

Cement boards with a ½ inch thickness can be used as a tile backing for flooring instead of ¼ inch boards, but where ½ inch cement boards are most commonly used is on walls underneath tiles.

The additional thickness makes the boards much more durable and will prevent cracks from appearing on tiles or in the grout in the event of the wall sustaining an impact. This could happen if a person slips and falls against the wall, which is not uncommon in the bath or shower.

A ¼ inch cement board would not be strong enough to sustain the weight between stud spacing, resulting in damaged tiles. The key requirement for wall backing is that it will not flex between studs, which can be as much as 16 inches apart.

This is where ¼ inch and ½ inch cement boards differ because ¼ inch boards will flex under weight in this distance, while ½ inch boards will remain straight. This makes it the ideal backing for wall tiles, while ¼ inch cement boards should be reserved for countertop and floor applications, with a few exceptions.

Quarter Inch Cement Board Exceptions

There are a few instances where it is acceptable to use ¼ inch cement board underneath wall tiles, though if possible, it is always advisable to use ½ inch cement boards under wall tiles for superior strength and durability. You can use a ¼ inch cement board for wall tiles surrounding bathtubs if you first install plywood beneath the cement boards.

Measuring ¼ inch thick itself, the plywood, when combined with a layer of ¼ inch cement board, will create the required ½ inch thickness to properly support the tiles and prevent flexing between studs.

This might be a less expensive way to achieve a strong, water-resistant layer beneath your tiles if your budget is tight, though it will result in more work and a potentially longer project.

Before going ahead with this option, you should first consult your local building code because it may not be permitted in your area.

You will also need to install a waterproof membrane between the plywood layer and the cement board layer to prevent moisture from seeping through to the wood and causing issues with rot, mold, and swelling.

Cement Board Alternatives

On bathroom walls, you will not need to use cement boards to cover the whole room. Instead, you just need to fix it behind areas that will come directly into contact with water, such as behind the bath or shower.

If you plan to tile all of the walls, then there are certainly benefits to using cement board on every wall. For example, you will have peace of mind that the bones of your home have the ultimate protection against moisture, and it will be easier to install than creating a mesh of various wall materials.

However, if you want to leave some of the walls un-tiled and paint them instead, you can transition from cement board to drywall in parts of the room that will not get wet.

Another possible option is using fiber cement board as tile backing because it is moisture resistant and can also be painted, unlike cement boards.