Foam is a popular crafting material that is used in a wide variety of applications to create various items, such as floral arrangements, costumes, and window displays. To get the most out of your foam and achieve the highest quality finish, a foam cutting tool will be your new best friend.

Foam-cutting tools can also make your crafting experience more efficient and enjoyable; however, the type of foam-cutting tool that is most suitable will depend on what type of project you will be using it for.

Types of Foam Cutting Tools

The most popular types of foam cutting tools are:

Hot Wire Knife

A hot wire knife is a tool that features a smooth blade. Unlike most knives, this blade doesn’t cut through foam by being sharp, but instead, the blade heats up so that it can easily slice through the foam, melting the foam to separate it as it moves. These tools can be powered by battery or mains electricity, and both kinds have advantages and disadvantages.

A battery-powered hot wire knife might be more convenient in terms of portability, and you won’t be restricted to using your knife in an area that has a mains power socket; however, you might face the inconvenience of your tool running out of battery while you’re in the middle of a project. Whichever type of power source a hot wire knife is run on, these tools are undoubtedly among the best for easily cutting through foam with minimal mess.

Unlike serrated knives, the blade on a hot wire knife is smooth, and so it doesn’t chip off small pieces of foam as it cuts. When looking for a hot wire knife, you should consider the length of time the knife takes to heat up and how good it is at maintaining temperature. It can be frustrating putting our project on hold while you wait for the knife to reach the necessary temperature.

Though a hot wire knife is ideal for many foam cutting projects, it carries obvious safety risks and should only be used by competent adults. Keep the tool out of reach of children to prevent potential danger. The blade on a hot wire knife typically has two curved blades that join together at the center to form a semi-circle or ‘Y’ shape. The shape allows you to create bevels in your foam and is great for making decorative cuts.

Styro Cutters

Styro cutters are very similar to hot wire knives, but they will have just one blade or needle pointing out of the handle. This needle heats up to slice through the foam. These types of tools are great for carving out fine detail in foam and for precision work.

To effectively use a styro cutter, you need to move it slowly through the foam, allowing the heat to do its job. If you move too quickly, it is possible for the needle to snap, leaving you with a messy cut and a tool that needs fixing. These are low-maintenance cutters that are easy to care for with a few simple steps.

After using the styro cutters, you should always clean the blade with a sponge while the needle is still warm. This will prevent any loose fragments of foam from getting stuck to the needle and will ensure that it doesn’t blacken.

Failure to do this will result in a messy and bumpy needle that will need to be replaced before you can use the tool again. You can also get various-sized needles to fit your tool, with finer needles being more appropriate for delicate jobs.

Foam Cutting Saw

The foam cutting saw features a large blade that is finely serrated, and this is joined to a flat and heavy base with wheels so it can glide along the foam. When powered up, the blade makes lots of very fast but tiny vibrations, causing the knife to swiftly slice through the foam.

This tool is excellent for ensuring consistency in cutting. It produces perfectly straight edges, so you won’t need to worry about your cuts’ angles or their quality. This is a serious piece of kit, which is ideal if you have a lot of foam to cut and want to ensure a professional finish.

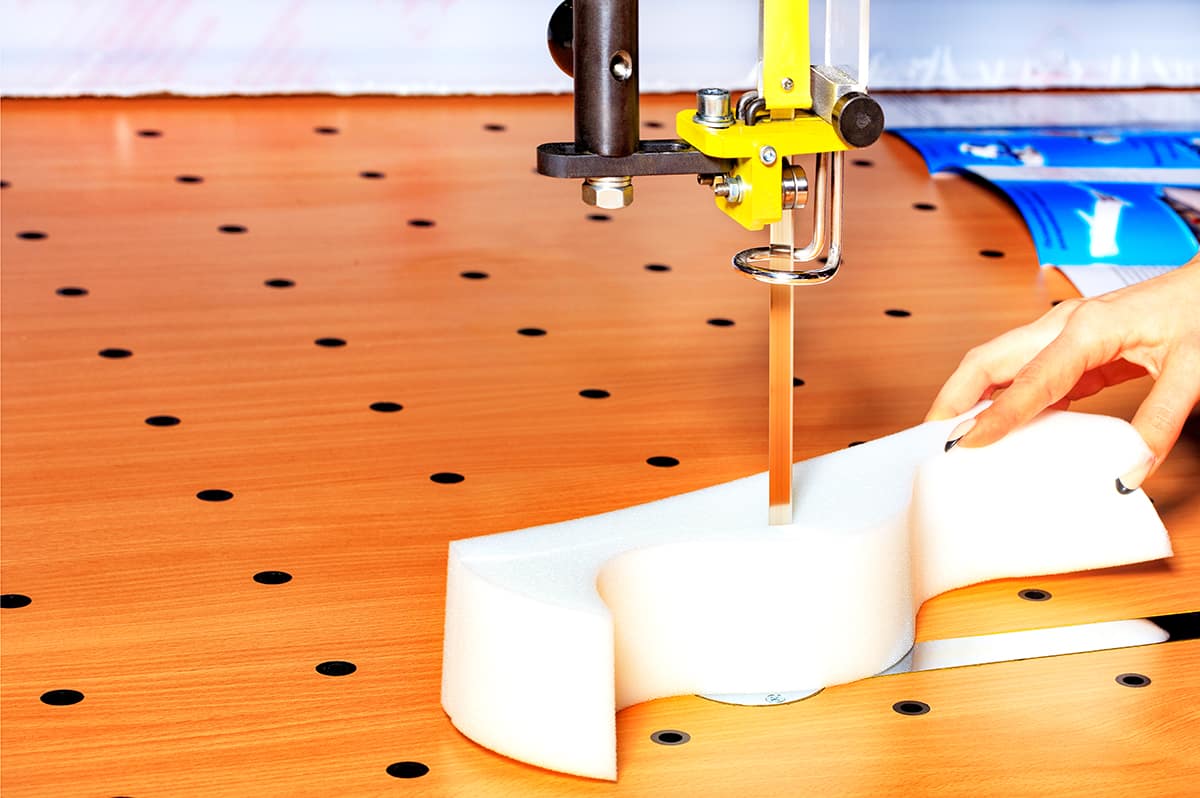

Hot Wire Scroll Table

This tool combines the premise of a hot wire knife with a work table so that you move the foam around the table rather than the knife around the foam. The benefit of this tool is a greater level of control, which will arguably lead to neater and more precise cuts.

These tables also generally come equipped with added features to help you in your foam cutting, such as an attached protractor, a measurement grid, and a lockable feed bar for the foam. Hot wire scroll tables cut with a needle that heats up, just like a hot wire knife, and these needles can reach temperatures of up to 360°F, making for smooth and clean cuts.

Specialized Blade and Saw

A traditional serrated blade will chew up the foam as it cuts, making for a messy edge and leaving shreds of foam gathering around you. A specialized blade, however, will slice through the foam more neatly and reduce the amount of displaced foam and dust created. Ideally, you should find a blade with a ceramic coating, as this will help to reduce friction and result in a cleaner cut.

Utility Knife

If you don’t cut foam often enough to warrant investing in a specialist tool, then a utility knife is a great alternative option. These are basic tools that you can pick up for a low cost at any hardware store, or you may already have one hanging around in your home or garage. These are multipurpose tools that can cut through foam precisely and with relative ease.

Foam does have a habit of dulling the blade of a knife, so choose a knife with a blade that can be easily replaced, and keep a check on it to make sure you aren’t working with a dull blade, as this will result in rough cuts.

Rotary Tool

A rotary multi-tool, also often known by the brand name ‘Dremel,’ can be useful in creating some, though not all, foam cuts. This tool comes with various attachments that spin at high speed, allowing them to cut through certain materials.

This tool can be useful in making decorative cuts in foam, but it will not perform the job as well as other foam cutting tools such as a hot wire knife, which have been designed with the specific purpose of cutting foam in mind.

Foam Cutting Tool Features

Stand

Some foam-cutting tools will come with a freestanding stand, allowing you to put your tool in a safe place for a few moments while you need to use your hands for something else. This is a great accessory for cutting tools that heat up, as laying the hot tool down on a table could cause it to burn or melt the table, depending on the material the table is made from.

A stand provides you with a convenient place to rest your tool while it cools down or heats up and allows you to be hands-free for longer. If your tool doesn’t come with a stand, you can buy them separately; just pay attention to the size to be sure it is compatible for holding your cutting tool.

Case

Many foam-cutting tools will come with a case as part of the set, which is great because it gives you a custom-made box or pouch in which you can keep your tool safe. Having a designated space for your tool will help to ensure it is stored properly and prevent it from getting damaged while in storage, and it will also help to prevent the tool from accidentally getting into the wrong hands if it is safely packaged away.

If the purchase of your cutting tool does not come with a case, it would be wise to invest in a small plastic box of a similar size to store your tool in. This will also enable you to keep any extra blades or additional components together and help with organization.

Tip Set

Some foam cutting tools will have the feature of being able to be used with a variety of different tips, blades, or needles. Rather than having to purchase different tips separately and build up your collection gradually, it is convenient if your tool includes a set of various different tips that are compatible. This will enable you to use specific purpose-designed tips on intricate foam cutting, for rounding edges, or for creating bevels.

Having a variety of different tips to choose from can allow you to create foam pieces with a selection of finishes. If you only need to cut straight edges, then you may find additional tips are not necessary, and you can get by with one straight tip, however for cutting curved edges or fine details, then purpose-designed tips can be very useful.

Power Source

The power source used for your cutting tool can affect how you use it. Hot cutting tools will either be powered by batteries or via a mains electrical socket. The advantage of battery-powered tools is that they are portable, so if you are concerned about being able to use your tool wherever you go without worrying about the nearest mains power supply, then a battery-operated cutting tool is your best option.

The main disadvantage with battery-powered cutting tools is that when the batteries near their end of life, the tool will not heat up as quickly or get as hot as it once did, making cutting frustrating and inefficient. You may find that your battery needs replacing in the middle of a project, which can be quite inconvenient.

You should also consider the fact that batteries can be expensive to replace, so while a battery-powered tool may be less expensive to buy than a corded tool, they may cost you more to power in the long run when you factor in continually buying new batteries.

If you are not concerned with portability, then a corded foam-cutting tool may be a better option. These tools offer more reliability as you can be sure they will work as long as you have access to the main power outlet. If you are looking for a corded foam cutting tool to buy, then you should look for one with a long cord to ensure that you don’t have to sit very close to the power outlet to operate your tool.

A longer power cord will give you more flexibility with regards to where you use your tool. That being said, if you do have a corded power tool, you could always extend the cable with an extension lead, which would allow you to work further away from the power socket and even work out in your garden in pleasant weather.

You can expect corded foam-cutting tools to cost more to buy than battery-powered equivalents, but they will also be more powerful and have a longer life expectancy.

Uses for Foam

Floral Displays

Florists commonly use foam as a base for floral displays and arrangements. They use a wide variety of shaped foam pieces, such as circular pieces, to create wreaths and blocks to create centerpieces. For customized floral displays, they can cut larger foam pieces into specific shapes to create unique displays, and to do this, they will need to utilize foam cutting tools.

Customized floral displays such as this are common for funerals. For example, if someone dies who loved to roller skate, then the family may request a floral arrangement be created in the shape of a roller skate.

Table Centerpieces

Table centerpieces utilize foam as a base from which to work so that the centerpiece is sturdy. Centerpieces can be made from any number of things, for example, pine cones, fruit, candles, branches, seashells, ribbons, and dried berries.

These types of items can be secured to the foam with a hot glue gun, or they can be pinned down to the foam with wire. In these instances, though the foam cannot be seen in the final centerpiece, it acts as an essential foundation to hold the finished item together.

Centerpieces using foam as a base can be created to decorate tables at weddings, birthday parties, reunions, anniversaries, or any kind of celebration. They are great for helping to create a theme for a party, such as a beach theme with a coastal style centerpiece, or to help add to a color theme.

Halloween Costumes

Foam is a great material for creating unique and inventive costumes for Halloween or other events. With the right foam cutting tool, you can make shapes out of foam and stick them together using a hot glue gun or wire to create original costumes.

You could also spray the final shape with paint to add to the effect. Possible costume accessories you could make out of foam could include foam guns, swords, or shields for cowboy or superhero costumes or foam wigs for a cartoon-like hairstyle.

You could also create the main costume components out of foam using appropriate foam cutting tools. For example, create a giant food item to dress up as, like a pizza or a carton of popcorn. The options really are only limited by your imagination.

Upholstery

Foam can also be used in upholstery, to bulk out the arms of sofas and armchairs, or as a base underneath the soft cushioning of seating furniture. If you are upholstering furniture, your foam will need to fit in the designated space exactly, so a precise foam cutting tool will be vital. You can also use foam as a base to create a bed headboard or a window seat.

Sculptures

Artists can utilize foam when creating sculptures, using foam in a similar way that you would use it to create a table centerpiece. In sculpting, foam can be used as a base to attach other components, making it a strong structural base for sculptures.

Window Displays

Foam is often used in window displays for storefronts as it is a low-cost item that can be secured easily and work well as a base on that other items can be displayed. Most often, foam blocks of various sizes will be used for this purpose, though other types of foam can be custom-made into specific shapes to create unique window displays.

Foam is a great material for creating winter window displays as it can be shaped to look like a snowman or other snow-covered structures. A foam-cutting tool will help you achieve a professional finish when creating high-quality window displays.

Foam Safety Tips

Cutting foam can be a fun and enjoyable hobby, but you also need to take care to follow safety precautions to ensure you don’t cause any damage to yourself or others. When operating tools with blades, you should take care to keep your hands a safe distance from any blades. Many foam-cutting tools utilize high levels of heat, which can cause third-degree burns to the skin if they come into contact.

When using heated tools, it’s a good idea to wear protective gloves as a precaution. When using foam cutting tools, it is also possible for loose bits of foam or tiny fragments of dust to fly out that could become lodged eyes.

For this reason, many people choose to wear protective safety goggles to shield their eyes when using foam-cutting tools. For workers, it’s recommended to wear cut-resistant gloves for safe cutting. Always remember to store your tools safely so that they are kept out of reach of children and do not accidentally cause harm.

Proper Foam Disposal

Proper disposal of foam after you have finished with it is an important consideration when crafting with foam. Styrofoam is a man-made material that is not widely recycled; however, it is worth checking your local recycling regulations as some areas are able to dispose of Styrofoam in an environmental way. The problem with recycling Styrofoam is that it is quite a costly operation, which is why it is only offered in a few select areas.

Many people assume that Styrofoam is recyclable and add it to their recycling trash, but it’s very important to check because if you add it to your recycling when your local area doesn’t consider it a recyclable material, then your whole bag or recycling will be contaminated and will be added to the non-recycling trash heap, adding to landfill.

If you cannot recycle your Styrofoam, you should be sure to remove any materials that are attached to it and can be recycled, such as cardboard or paper, and add these to your recycling.

The Styrofoam itself will then need to be added in with regular trash, but a good space-saving tip is to break it down into smaller pieces first so that it doesn’t take up all the room in your garbage can.

If you are fortunate enough to live in an area that does accept Styrofoam for recycling, you’ll need to be sure to use standard uncolored Styrofoam in your projects. If you use dyed Styrofoam, this will render it unsuitable for recycling and will need to go in with your regular trash.