In terms of cement boards, there are two popular manufacturers, which are Durock and Hardiebacker. Depending on your preferences, you may pick one brand over the other.

So, what are the differences between the two cement board brands? To give you a better view, here are some important details about Durock and Hardiebacker.

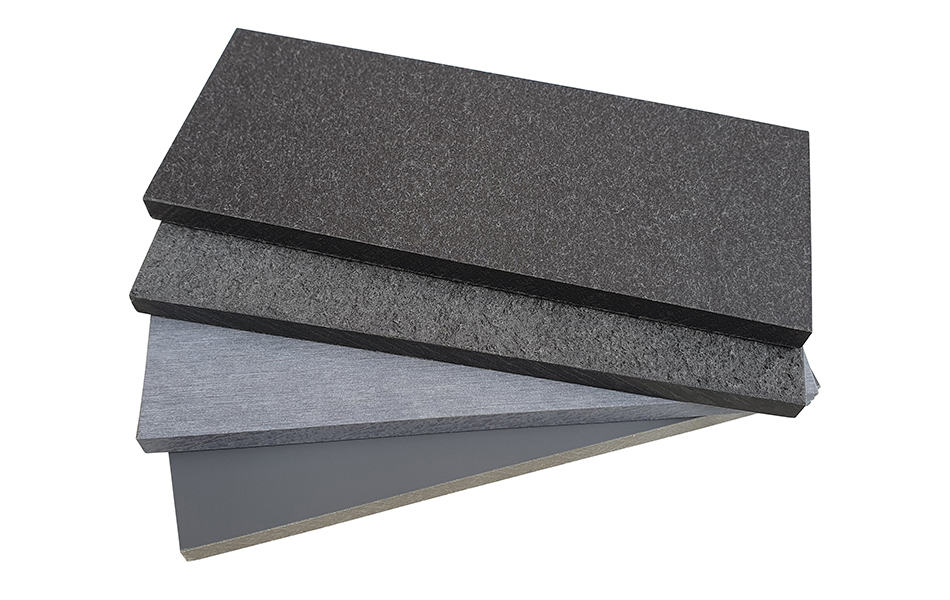

What are Cement Boards?

Compared to wood, most contractors prefer cement boards because they contain inorganic materials, like limestone flour, fiberglass, silica, cement, and water. Keep in mind that the organic materials typically found in wood promote rotting and decomposition. As such, cement boards are preferred over wood to prevent frequent replacement of the board.

Cement boards are usually made using a combination of cement and reinforcing fibers. Generally, they come in sheet form with a thickness of about 1/4 to 1/2 inches.

For its purposes, cement boards are typically used to add strength to a wall surface. As such, it is often used as a base for stucco systems. Aside from that, it can also be used for tile backing.

What is Durock?

As mentioned, Durock is a cement board manufacturer, and the company is based in Canada. For the past 40 years, this family-owned business has been manufacturing finishing products with excellent quality.

As for Durock cement boards, they are usually made of reinforced fibers and cement. Additionally, Durock cement boards can be nailed or screwed easily against a wall surface.

Usually, cement boards can only cover vertical surfaces. However, the Durock cement boards are durable enough for shelving. As such, you can use this cement board for backsplashes and kitchen counters.

Advantages:

- It has a smooth side, which makes it adhesive.

- It comes in a variety of sizes.

- It offers excellent adhesive coverage.

- It is waterproof.

- Its thermal expansion is low.

- It has noncombustible fibers.

- It is flexible and versatile.

Disadvantages:

- It can’t handle a force of more than six psi

- It may disintegrate, especially if left for about 90 days or more.

- The steel framing used for this cement board must be massive.

- When used for floor applications, it has a minimum deflection limit.

What is Hardiebacke?

Hardiebacker is another manufacturer of cement boards, and it is one of the most recognized companies in the construction industry.

Since 1980, manufacturers of cement boards, like Hardiebacker, have used reinforced fibers. The reason is that reinforced fibers can increase the quality of cement. Plus, the cement used for creating these cement boards is glass-free; thus, they are cleaner. Also, the cement boards contain fiber mesh, which provides exceptional support required for a strong and high-quality cement board.

Overall, Hardiebacker cement boards can also be used as tiles. Plus, it is an excellent alternative to plasterboards and plywood. Also, it can be used for kitchen counters and floor tiles. Lastly, Hardiebacker cement boards can ensure strength and safety.

Advantages:

- It has MoldBlock technology.

- It is waterproof.

- It is dimensionally stable.

- It is easy to cut and dismantle.

- It is tested under high-quality standards.

- It comes in a variety of sizes and thicknesses.

Disadvantages:

- It can’t withstand a lot of force.

- Its steel framing must be massive.

- It requires specialized installation.

- Its upfront cost is high.

The Difference between Durock and Hardiebacker

As mentioned, Durock and Hardiebacker are two of the most popular cement board brands in the market. So, what are the differences between these two brands?

Resistance and Durability

Compared to Hardiebacker cement boards, Durock cement boards have glass mesh. As such, Durock cement boards are harder to cut. Additionally, installing it requires precaution. On the other hand, Hardiebacker cement boards are lighter; thus, you can install them easily.

In terms of durability and resistance, cement boards from Durock are more durable. Still, it can break when a certain amount of force is applied. Still, cement boards are more resistant to force compared to gypsum boards and plywood. In fact, when properly maintained, cement boards are long-lasting. Plus, they don’s shrink; thus, they are more resistant and durable.

Flexibility

Both Durock and Hardiebacker cement boards are flexible because they contain a polymer-based fiber mesh. As such, they can be stick on contoured or curved surfaces. Aside from that, they can also be used in walls, beams, ceilings, and columns.

Hardiebacker cement boards are more flexible than Durock cement boards. Remember, you can install flexible fibers with ease, resulting in an installation cost that is lower. Also, the thickness of the board can play a role in its flexibility because it allows the board to bend quickly and evenly.

Thickness

In general, the standard thickness of a Durock cement board is 1/4 inch, and it is ideal for countertops and floor tiling. Plus, the 1/4 inch thickness is ideal because it eliminates the trim when carpeting.

On the other hand, Hardiebacker cement boards come in two thicknesses, which are 1/2 inch and 1/4 inch. Keep in mind that 1/2 inch is the standard size for vertical installation. As such, you may need to use a 1/4 inch thickness if you’re going to use a Hardiebacker cement board with plywood.

Overall, Durock cement boards are thicker compared to Hardiebacker cement boards. The reason is that Durock cement boards incorporate a glass mesh.

Adhesiveness

When it comes to adhesiveness, Durock cement boards are easier to stick to surfaces. The reason is that it is more textured, allowing it to stick firmly on a surface.

On the contrary, a Hardiebacker cement board has a smooth surface. Still, it can stick firmly on a surface, but its adhesiveness is less compared to Durock cement boards.

Installation Time

Compared to regular cement, installing cement boards are easier. To be specific, you all need adhesive and nails to install them. In fact, when an expert installs a cement board, he can finish the task within hours.

In terms of installation time, both brands of cement boards can be installed in a couple of hours. In fact, they are easy to apply as long as you follow the instructions in the manual. Even so, their installation time may vary, depending on the screws and adhesive that you will use.

Appearance

In terms of appearance, both Durock and Hardiebacker cement boards have different grooves and textured patterns. But, you can identify one from the other by their color. To be specific, Durock cement boards are darker in color, while Hardiebacker cement boards are light gray.

Durock VS Hardiebacker: Which is Better?

There is no clear winner when it comes to the battle between Durock cement boards and Hardiebacker cement boards. The brand that you will choose will still depend on your preferences and project.

For example, Durock cement boards are heavier and denser; however, these characteristics make the board difficult to cut and install. On the other hand, Hardiebacker cement boards are lighter in weight, so they are easier to cut and install. Plus, they also have an EZ grid pattern that allows you to cut the board with ease. As such, if you are looking for a board that you can install with ease, Hardiebacker is your best option.

Another example is the board’s thickness. For instance, you need to use a cement board with a thickness of about 1/2 inch. As such, your best option is Hardiebacker because their cement board comes in two thicknesses, which are 1/4 and 1/2 inches.

Aside from that, keep in mind that Hardiebacker cement boards are not approved for exterior use, but they have a lot of uses inside your home. On the other hand, Durock cement boards can be used for internal and external construction.

Frequently Asked Questions

Which is Better Cement Board or Backer Board?

Compared to the backer board, the cement board is widely used. However, keep in mind that a cement board has a disadvantage. To be specific, this type of board is heavy and hard. As such, it is difficult to cut. Plus, it may leave some crumbs that may eventually damage your tubs and shower bases, especially if you’re not careful.

Should I Waterproof My Cement Board?

As mentioned, cement boards are waterproofed. Plus, they can be exposed to moisture or water for a long period.

Which brand should You Use for Your Bathroom?

If you’re remodeling your bathroom, both Durock and Hardiebacker cement boards are great choices. The brand that you will pick will depend on the phase of your remodeling and your preferences.

For example, if you’re going to cover your bathroom floors and walls before installing the tiles, Durock is a preferred choice. Remember, this cement board is durable and waterproof, making it a good choice.

However, Hardiebacker is best used if you’re going to use the board under your bathtub or shower. The reason is that Durock is vulnerable to molds, plus it can damage enamel and porcelain. Aside from that, Hardiebacker is also a good choice for bathroom counters and small installations because of its flexibility.