Grandfather clocks, also called pendulum clocks, or longcase clocks, contribute greatly to the mood and mysticism of any room or hall. The contemporary versions of these clocks differ from previous models in that modern grandfather clocks neither include ancient clock elements nor need to be turned to display the correct time.

The idea of grandfather clocks invokes images of a towering, majestic oak clock in the corner, complete with a lengthy pendulum that is constantly vibrating.

Although the origin of its name is unknown, a grandfather clock is generally defined as a pendulum clock that has a length of more than 1.5 meters. The majority of these clocks stroke or chime at the end of an hour, while some may chime or ring after half an hour.

Grandfather clocks operate in one of the two main types of motions, eight-day or one day. A grandfather clock with an eight-day mechanism only needs to be set once a week, whereas one-day mechanism clocks need to be set every day.

For over three centuries, these antique clocks were widely used and regarded as the most accurate timekeepers. The traditional workmanship and royal majesty of grandfather clocks have ensured that the clocks have remained widely popular, even after so many years.

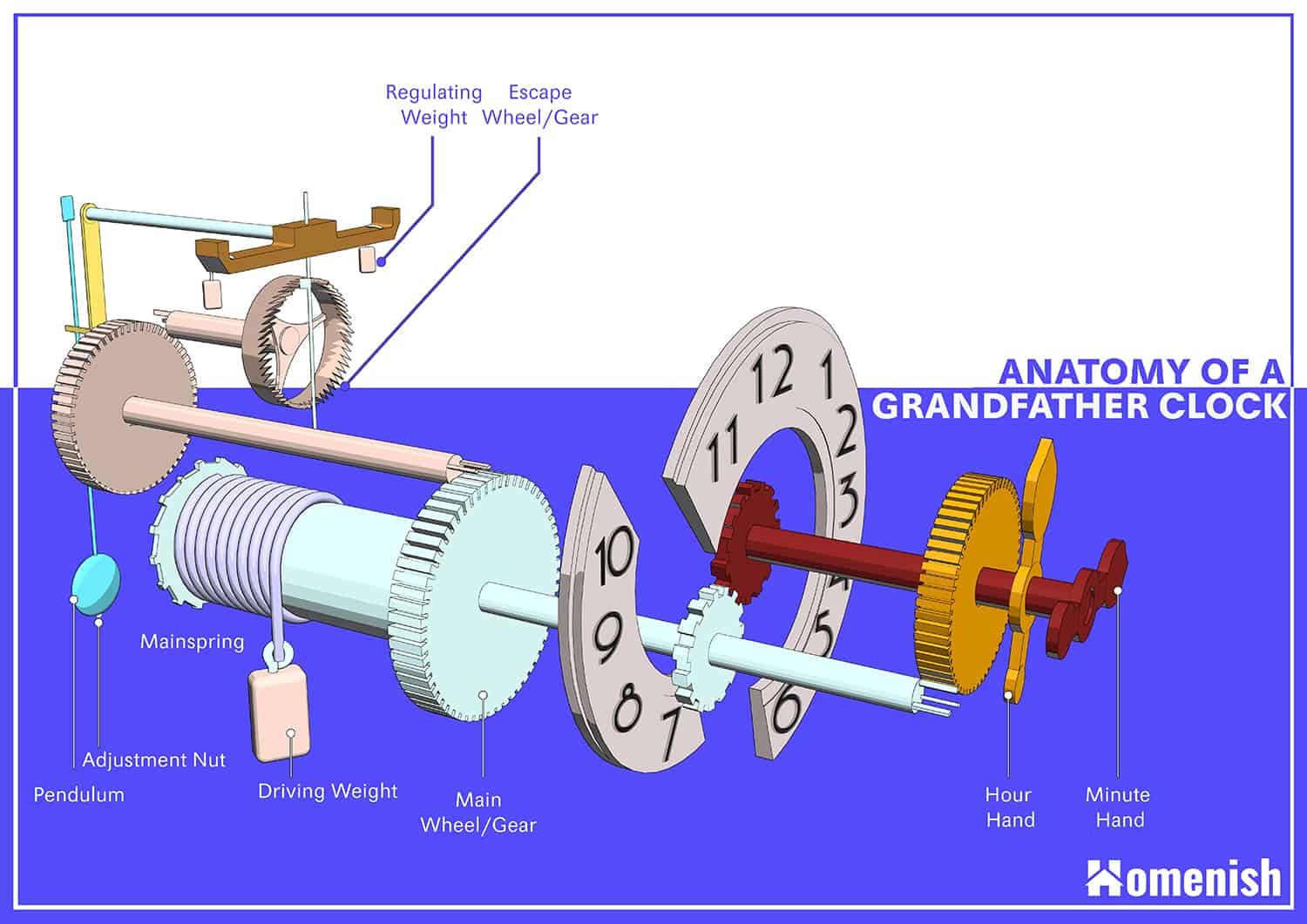

In this article, we’ll go over the main parts of a grandfather clock and how it works – illustrated by a 3D diagram. You may also read the parts of a wall clock to under their differences.

How Do Grandfather Clocks Work?

The movements lie at the heart of each pendulum clock. The hour/minute hand’s striking, chiming, and subsequent timekeeping are all dictated by the pendulum’s movement. The weights and hanging pendulum are essential components of every mechanical clock’s mechanism.

The timekeeping is regulated and adjusted by the movement of the pendulum. Three weights may be used in a pendulum clock to operate the clock’s striking, and chiming. Each of the three weights is unique and must be placed correctly to ensure optimal operation.

A chain or wire suspends the weights from the escapement apparatus so that they work in line with the mechanism. The clock may stop working if the weights are not adjusted over 7 days. The lifting of the weights is achieved with the help of a crank. A series of hammering rods of different lengths produce striking and chiming sounds.

Parts of Grandfather Clock

Each movement of a pendulum clock is due to the four fundamental internal elements that make it work. The escapement, gears, setting mechanism, and weight are all elements of the internal parts. Some external parts have been discussed below.

Escapement

The escapement was designed to ensure that the pendulum maintains a consistent swing. Clockmaker designed the pendulum, the anchor, and the escapement wheel as the three components of the escapement. The pace at which the other gears in the clock movement is determined by the escapement wheel. This escapement wheel has specifically designed teeth. The pendulum is attached to the anchor, which latches to the teeth of the escapement wheel.

The anchors have an upward U-shape and have two meeting points with the escapement wheel. One of the wheel’s teeth is allowed to traverse with each oscillation of the pendulum. The second hand of the clock moves continuously as a result of this.

The clock’s minute and hour hands move because of this basic principle, but the wheels that drive the minutes and hourly hands rotate after pendulum vibrations. As a result, the pendulum becomes a mechanism for releasing the potential energy stored in the weight.

Wheels / Gears

Also called gears, several wheels are installed between the weight and the escapement gear to achieve desired spinning ratios daily or weekly for convenience of operation. The weighted wheel travels relatively slower than other wheels between the opposite edges, enabling the weight to fall and release energy at steady rates.

Though the wheel of gear ratios are simple enough to comprehend, aligning each wheel to reach a hand on the grandfather clock face becomes tough. Tubular shafts are commonly used to conduct the operation of the hands of the clock – one inside the other to solve this difficulty. Also, with tubular shafts, organizing the gear to work continuously can be a challenging task.

Gear Trains / Wheel Trains

The speed from the mainspring to the weight is controlled by the gear train. The clock’s hands are connected to the teeth of different wheels in a wheel train. As a result, the hour hand moves slower than the minute hand.

Setting Mechanism

A tiny lever, or winder linked to a gear pulls the gear out of line with others to configure the working of grandfather clocks accurately. The setting mechanism brings the clock to a halt, permitting it to be turned and the time to be set.

Pendulum

The pendulum gives the clock potential energy, allowing it to oscillate at a steady rate.

There is a small adjustment nut below the pendulum which helps boost up or slow the clock speed if it is increasing or losing time.

Driving Weight and Main Spring

The clock’s power supply is provided by the mainspring. The mainspring could be a pulley that is turned by a driving weight on a cable. The power supply in several smartwatches and clocks is a metal string. This is sometimes referred to as spring winding since it preserves the mechanical power that is used to spin the clock’s movements.

The weight’s projected energy loss is represented by the unfolding of the string around the gear and consequent lowering of the weight. As a result, mechanical clocks should be reset regularly to replenish the stored energy of the weights.

Dial

The dial is the displayed face of the clock that records the revolutions of the escapement-driven gear train. In a nutshell, it uses spinning hands to show the time. A dial has numerals 1-12 on it in the most widely used displays. Subdials also display the date and lunar phases in certain clocks.

Chimes

The chimes are among the most notable and distinctive features that have helped to define the grandfather clock. A grandfather clock without a working chime is not regarded as authentic and genuine. A variety of wheels, pulleys, levers, and hammers will be required to make the chime operate properly.

Normally, chime sequences are sounded at the top of each hour, but quarter-hour chime sequences (the most renowned chimes sequences are Westminster quarters) were introduced to pendulum clocks in the twentieth century.

Origin of Grandfather Clocks

The sundial was man’s earliest timekeeping instrument. It was a device that measured the movement of a huge object’s shadow to calculate equal fractions of the day. A sundial is undoubtedly a useful tool for measuring time intervals, but because of the Earth’s eccentric orbital path, the time recorded by a sundial over a year might be less precise, and this left a lot of opportunity for advancement.

While sundials were perhaps the most popular tool for keeping time, they were not the only ones. The clepsydra (water clocks) and the clepsammia (hourglass) were also rare inventions. Water clocks worked by allowing water to leak through tiny holes in a vessel.

The process of making these mechanical gadgets for measuring time was highly costly. Further, temperature, wind speed, and the fluctuation in pressure inside the vessel all influenced the time interval between movements of the clock’s operation, causing the time to be inaccurate.

On the other hand, the hourglass told the precise time, but it took a lot of concentration to notice when the final grain of sand dropped and to flip it over quickly.

Fortunately, in 1658, because Robert Hooke developed the anchor escapement mechanism, the grandfather clock was born. The anchor system lowered the movement of the pendulum to 4°-6°, enabling makers of grandfather clocks to make use of longer pendulums with slower beats. The newer grandfather clocks used less energy, enabling clocks to function for longer periods than traditional sundials, hourglass, and water clocks. These were also more precise and produced minimal friction.

By 1680, a clockmaker from Britain, William Clement had created the first grandfather clocks. Later that year, the most famous British clockmaker, Thomas Tompion, began producing them as well. Grandfather clocks became popular all over England as well as in Asia and Europe. The average cost of grandfather clocks in England peaked between 1680 and 1800, limiting clock purchases to the comparatively wealthy. However, by 1800, salaries had grown to the point that many families in the lower-middle-class could afford grandfather clocks.

How to Take Care of a Grand Father Clock

Examine to see if your grandfather’s clock is balanced and steady. Ensure that the clock’s hands are neither contacting one other nor the dial of the clock. As the pendulum swings, ensure it doesn’t scratch or hit anything. Lastly, double-check that the suspension spring is not damaged and the pendulum is properly hanging.

The design and production of a grandfather or pendulum clock necessitate exceptional workmanship as well as a wealth of knowledge in physics and engineering. The concepts of energy and mechanics, along with the qualities of a pendulum that result in an accurate clock, remain an impressive feat.

Also, note that some grandfather clock components may not be found readily available in stores, therefore repairing a grandfather clock, especically clocks may cost a lot of money. To preserve the integrity and durability of each grandfather clock, it is important to take good care of them.