If you are designing glass features on a building, then you’ll need to work with standard glass panel sizes to ensure your designs can translate into reality.

Here we look at the standard sizes glass panels typically come in and other considerations you’ll want to think about when designing architectural drawings with glass components.

Glass Panel Sizes

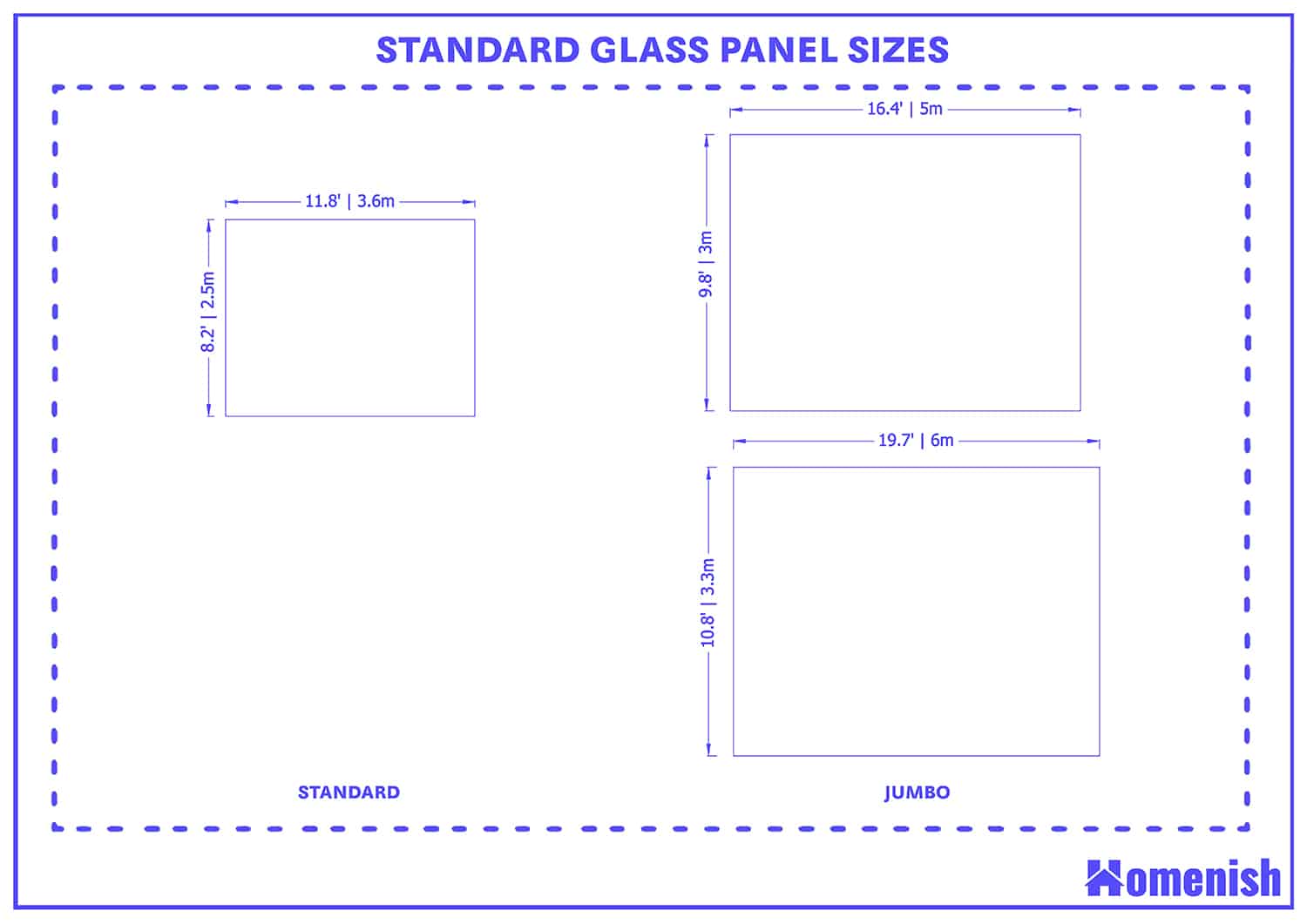

Standard

The standard size for glass panels is 2.5 meters by 3.6 meters, which is equal to 8.2 feet by 11.9 feet. If you order a standard glass panel, this is the size you can expect to receive.

If you want glass smaller than this, you can have a glazer custom cut your glass panels to size, from the original panels at full measurement. Glass panels come in this standard size to make the manufacturing process easier, and so designers who use glass know what they have to work with.

Jumbo

Jumbo glass panels are bigger than standard size panels, and these are what you will need to choose if the standard size of glass panels isn’t going to be big enough for what you have in mind. Jumbo glass panels come in two typical sizes.

The smaller of the two is 5 meters by 3 meters, which equates to 16.4 feet by 9.8 feet in imperial measurements. The larger size of jumbo glass panels is 6 meters by 3.3 meters, which is the equivalent of 19.7 feet by 10.8 feet.The largest jumbo panel of glass will cover a huge 19 square meters of space and weigh almost a ton.

Legally there is no limit on the maximum size of glass panels; however, most glass manufacturers create their own maximum glass panel limits in order to make sure the glass can be transported and that it is strong enough to make it fit for purpose.

Glass Considerations

When you are designing a building with large glass-paneled walls or glass panels on the roof, then there are other things to consider besides the size of the glass. Here we look at other elements that are necessary to think about when choosing glass panels for architectural projects.

Heat retention

Heat retention is really important for buildings that have a high proportion of exterior glass in their walls or ceilings. This is because, unlike solid walls built from brick or timber framing, you cannot insulate glass. Insulating walls and ceilings is important to make a building energy efficient.

Insulation will help to prevent heat from escaping a property, so that energy usage and energy bills will be low. Insulation also helps to keep buildings cool during warmer weather.

Without the ability to insulate, it’s important that one of the qualities of the glass you choose is its ability to retain heat. Heat retaining glass panels will help to keep energy usage low, reducing the impact on the environment, and it will also help to save money on energy bills.

Single pane glass is a poor option in terms of heat retention because it will allow 50% more heat to escape compared with double-paned glass. By using double-paned glass, you can cut energy usage and energy bills in half compared with single-paned glass.

If you really want to improve the heat retention properties of your home, opt for low emissivity glass, which will save up to 80% on energy usage and energy bills compared with standard single pane glass.

Acoustic protection

If you are building a property in an area where noise is going to be an issue, then consider using special types of glass for acoustic protection. Standard double-paned glass is going to offer better protection against noise compared with single pane glass, and it is especially effective at blocking out higher frequency noise.

If you want to ensure ultimate protection against external sounds, you can use polyvinyl panes, which also blank out low-frequency sounds. To minimize the noise levels in an airport or train station, use double-paned glass panels where each individual panel has a greater distance between them than usual.

By creating a larger gap between each glass panel, the level of noise heard inside the building can be lowered by several decibels.

Vandalism protection

Laminated glass is ideal for protection against vandalism and in other scenarios where extra strength is important. Laminated glass will be made from two glass panels that have a layer of laminate film in between them, or you can also get double or triple laminated glass panels with extra layers of laminate film.

These are more difficult for vandals to break compared with ordinary double-pane panels because you would need to break through the first layer of glass, then the laminate film, then the second layer of glass, in order to gain entry to a building through the glass panels. This would be a time-consuming process, during which time an intruder is likely to set off alarms and be spotted or scared off.

This type of glass is often a favorite among expensive luxury homes, which may be more likely to be the target of break-ins and theft. Laminated glass also works well for glass floors because it has additional strength to ensure it won’t crack under heavy weight or pressure from numerous people standing on it at once.

Mechanical resistance

Glass panels that are used in moving parts of buildings, such as doors, will need to be made from a glass that has been tempered. This is a chemical treatment that increases the strength of the glass so that it won’t crack under heavy mechanical use. Tempered glass also offers increased protection against excessive heat.

If your building is located in an area that expects high temperatures, regular glass panels are susceptible to breakages due to intense exposure to sunlight and heat. Prevent these issues by opting for tempered glass, which is much more resistant to the pressure caused by excessive heat.